A current sensor measures electric currents and turns them into a quantifiable output. This data can then be used for control, monitoring, or protection across various sectors.

Industrial current sensors provide real-time data that helps cut down on waste, reduces downtime and allows for better control of energy use. They help prevent breakdowns and keep machines running by continuously monitoring their performance.

In this article, we will take a closer look at current sensors, what they are used for, the different types of sensors used in industries, the effect they have on industrial efficiency and what to consider when choosing a current sensor.

Current Sensor Technology: Key Concepts Explained

A current sensor is a device that detects an electric current passing through a conductor and converts it into an easily measurable output voltage. This allows workers to monitor power use and provide diagnostics for electrically powered equipment. Depending on the type of current sensor, they may be capable of measuring both AC and DC currents.

There are many different types of current sensors and they can be categorised based on the fundamental physical concept underpinning their construction and how they detect electrical current. These include Hall Effect, Ohm’s Law, Faraday’s Law of Induction, Magnetic Field, and Fibre-Optic current sensing.

What Does A Current Sensor Do?

A current sensor measures the flow of electrical current in a circuit and provides real-time data on how much current is passing through. This is used to monitor and control electrical systems, help control energy use, and improve safety.

Current sensors can be used in applications like motor control, battery management, and power distribution. Excessive current can damage equipment, cause overheating, and lead to system failures.

Types of Industrial Current Sensors

Sensor Type | Definition | Category (Physical Principle) | DC Capability | Common Applications | Classification |

Hall Effect | Measures current by detecting magnetic fields generated by the current flow. | Magnetic Field (Hall Effect) | Sim | Motor control, automotive systems, energy monitoring. | Non-Invasive, Isolated, Wide-Bandwidth |

Shunt Resistor | Measures voltage drop across a low-resistance element to calculate current. | Resistive (Ohm’s Law) | Sim | Power supplies, welding systems, battery management. | High Precision |

Rogowski Coil | Non-invasive coil that measures AC current by detecting the magnetic field. | Electromagnetic Induction | Não | Power monitoring, fault detection in high-current systems. | High Current, Non-Invasive, Wide-Bandwidth |

Uses a magnetic core and field reversal to measure weak magnetic fields. | Magnetic Saturation Electromagnetic | Sim | Precision current measurement, aerospace, and research. | High Precision, Isolated | |

Fibre-Optic | Uses optical fibres and the Faraday effect to sense current in high-voltage systems. | Faraday Effect (Optical) | Sim | High-voltage power grids, isolated current sensing. | High Current, Isolated |

Current Transformer (CT) | Steps down high AC currents for safe measurement. | Electromagnetic Induction | Não | Power distribution, energy auditing, grid management. | High Current |

How Current Sensors for Industrial Applications Improve Efficiency

Battery performance and system accuracy help address range concerns and enhance the efficiency of electric vehicles. Accurate current sensors improve industrial efficiency by reducing range anxiety and providing system-level data in electric mobility.

Current sensors help optimise powertrain design and lower costs by delivering precise information on battery health, state of charge, and inverter performance.

Energy Management and Efficiency

Smart meters, energy monitoring systems, and demand-side management apps use current sensors to measure energy usage in various commercial and industrial settings.

In industrial plants, current sensors continuously monitor equipment’s electrical consumption. This allows for better energy usage analysis and detection of inefficiencies.

Process Control and Automation

In process control systems, current sensors provide precise measurements of current flow which, in turn, enable fine-tuned adjustments to operational parameters such as speed, pressure, and temperature. They are also needed for the proper functioning of automated systems.

Current sensors used in industrial automation make sure processes are efficient while minimising variability. They detect issues in real-time and allow for immediate corrective actions.

Predictive Maintenance and Fault Detection

Current sensors continuously monitor equipment health and track electrical load and consumption patterns to identify irregularities such as overloads or unusual current spikes. This is important as these irregularities can often signal developing faults.

Current sensors enable maintenance teams to detect anomalies early and address issues before they escalate. Early fault detection improves operational reliability and reduces the need for additional maintenance. This effectively prevents downtime and extends the life of the equipment.

How Do I Choose a Current Sensor for Industrial Needs

By now you’re probably wondering, how do I choose a current sensor?

The appropriate current sensor depends on your intended use and specific industry. If you’re looking for a current sensor for industrial use, the key things to consider are accuracy, range, sensor type, environmental factors, and pricing.

Remember, knowing is half the battle. Knowing what that current is doing or could do is essential to choosing the right current sensor.

Factors to Consider When Selecting a Current Sensor

The right sensor will not only provide accurate measurements but also fit within the environmental and operational constraints of the system. When selecting a current sensor, consider factors such as measurement range, accuracy, and installation environment.

The measurement range refers to the sensor’s ability to measure a specific range of current, from minimum to maximum levels, without overload.

Accuracy indicates how precise the sensor’s readings are, which is important for systems requiring exact measurements to maintain efficiency.

The installation environment covers the conditions such as temperature, humidity, and exposure to dust or chemicals, where the sensor will operate.

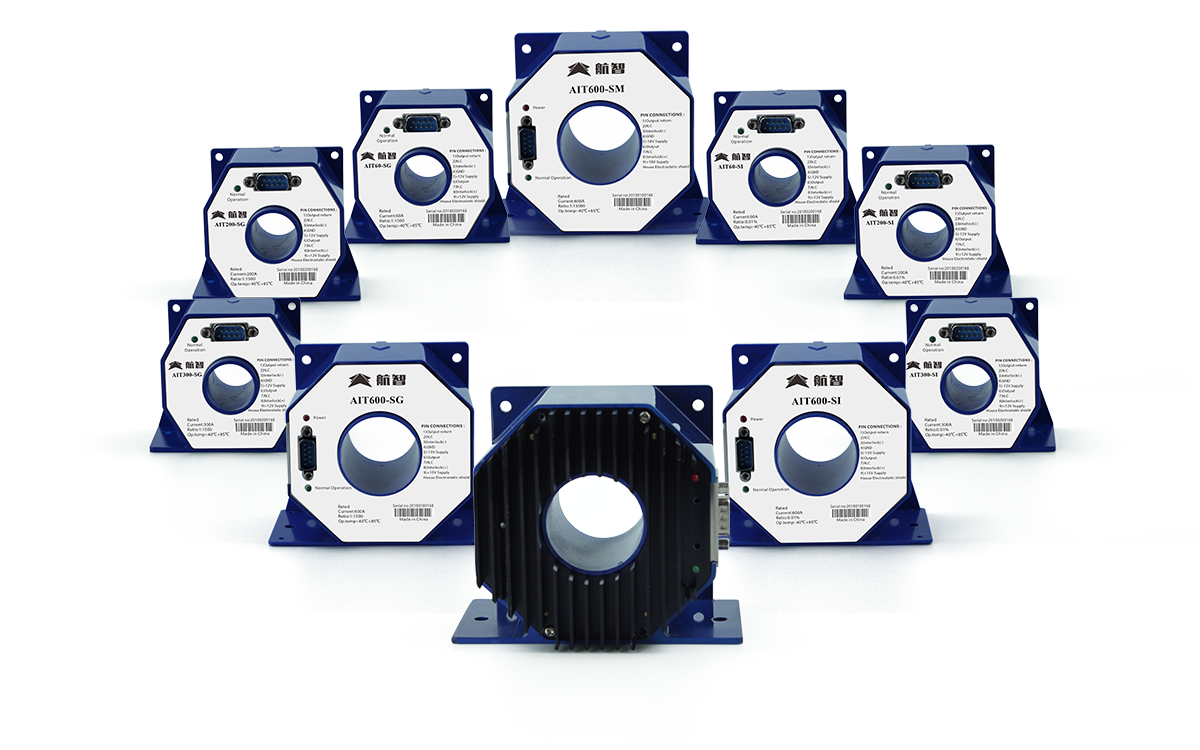

Boost Your Industrial Efficiency with Hangzhi Precision’s Current Sensors

Current sensors’ precise control and monitoring of electrical currents are the key to a wide range of industries. These sensors deliver instant monitoring and their versatility makes them a necessity for providing real-time feedback. This allows for both faster and more accurate sensing compared to traditional software-based monitoring.

Current sensing technology offers a reliable, cost-effective way to track circuit performance in order to maintain operational stability.

Hangzhi Precision’s high-performance current sensors can provide the accuracy and speed you need for more efficient monitoring. Contate-nos today to learn more.