The current sensor is mainly used in the fields of automatic control and remote control to realize real-time online data monitoring. It is a detection device that can sense the information of the measured current and can transform the sensed information into electrical signals or other required forms of information output according to certain rules to meet the requirements of information transmission, processing, storage, display, recording and control. The installation and fixation of the current sensor before formal use is also very important. Let’s talk about it in detail below.

Tartalomjegyzék

Current sensor installation and fixing

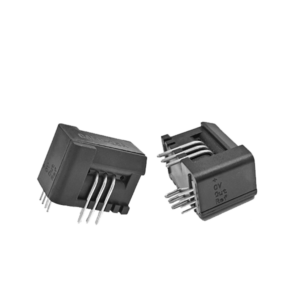

Current sensors are fixed in two ways: PCB and disc installation.

PCB installation

Generally, the primary measurement signal of sensors installed on PCB is relatively small. The output end of the current sensor adopts pin needle or SMD method, and the welding can be performed according to the welding process of general devices. Since some sensors are not filled with glue inside, cleaning should be avoided as much as possible.

Disc installation

Generally, the primary measurement signal of sensors installed on disc is relatively large, and the volume is also relatively large. In the specification of the current sensor, the spacing and aperture of the mounting holes are provided, and the size of the screws used for each mounting hole and the tightening torque will be clearly stated. The recommended torques are verified and evaluated by the design engineers. When installing, the torque recommended in the specification must be strictly followed, otherwise it is easy to cause the shell to break. Especially for glue-filled sensors, once the shell is broken, it cannot be repaired, which will cause economic losses and troubles in construction.

Installation direction

There is an arrow on the shell of each current sensor. The direction of the arrow represents the flow direction of the measured current. When the primary side of the sensor is connected to the measured current, it is necessary to ensure that the measured current and the flow direction are consistent with the direction of the arrow shown on the sensor. Otherwise, the output signal of the sensor will be reversed.

There are positive and negative primary voltage poles on the shell of each voltage sensor, representing the positive and negative poles for connecting the measured voltage signal. Some sensors also have a ground output terminal. Usually, this terminal is connected to the shielding layer and must be connected to the protective ground to play a shielding and anti-interference role. It is worth reminding that although the sensor can be used for both AC and DC, the direction of the primary side connection will also bring about changes in the secondary side output, and the primary and secondary side waveforms will be reversed.

Hangzhiról

Shenzhen Hangzhi Precision Electronics Co., Ltd. is a technology-leading enterprise dedicated to the research and development, production, sales and solution customization of high-precision current sensors, voltage sensors and high-precision electrical measuring instruments. We strive to build a well-known brand of fluxgate precision current sensors and precision electrical measuring instruments in the DC field, and strive to develop into an internationally leading leader in precision electronics in the field of DC systems.