r&d Background for High Current Sensor

As one of the main sources of renewable energy, photovoltaic power generation has been widely used and developed rapidly around the world in recent years.

With the development of the photovoltaic industry, the application of high-voltage photovoltaic systems is becoming more and more extensive. This development trend is mainly due to the consideration of improving system efficiency, reducing line loss, reducing system cost and meeting the needs of large-scale photovoltaic power plants. Higher voltage levels can increase the efficiency of photovoltaic cell modules, reduce energy loss, reduce resistive losses, reduce material usage, simplify power system design, and improve overall economics.

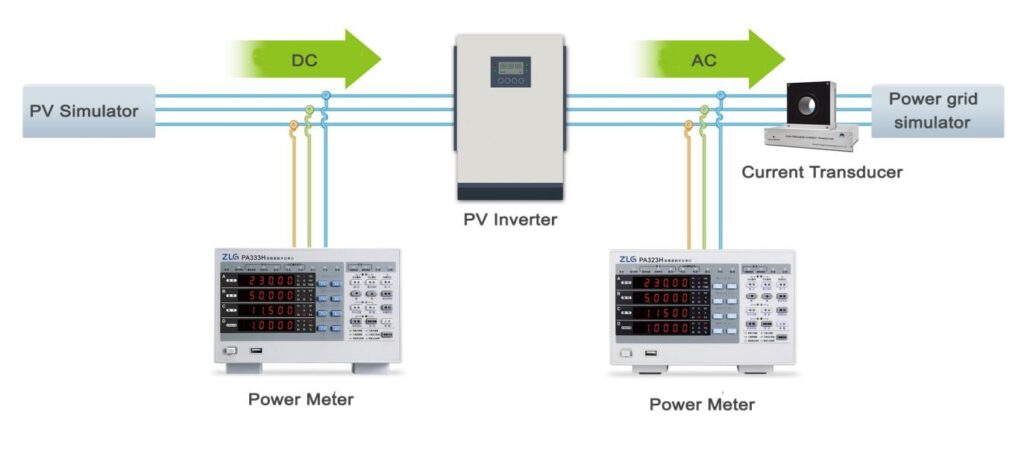

Photovoltaic inverters play an important role in photovoltaic power generation systems and can directly affect the power generation efficiency of solar photovoltaic systems.Its main function is to convert the direct current generated by the solar panel module into an electronic device with adjustable frequency alternating current, which can be fed back to the commercial power transmission system or used by the off-grid system. In order to ensure the quality and performance stability of photovoltaic inverters, factory testing is an essential. In high-voltage photovoltaic systems, due to the higher voltage and power requirements, a large-capacity inverter is usually required to convert the direct current generated by the solar photovoltaic panels into alternating current. Since the AC current output by a large-capacity inverter may be very large, in order to ensure the safety and stability of the system, a high-current sensor is required for current testing.

Pain points of using Tradition method

In high-voltage photovoltaic systems, photovoltaic inverter testing involves high current and voltage, so when selecting a current sensor, special attention must be paid to its range, accuracy and stability. At the same time, the safety and anti-interference ability of the sensor should also be considered to ensure the accuracy and reliability of the test results.

However, when faced with the requirements of photovoltaic inverter testing in high-voltage photovoltaic systems, traditional Hall current sensors may have some limitations, especially in large current ranges, and their accuracy and stability are far from enough to meet the needs. Therefore, in order to ensure the accuracy and reliability of the test, we need to find a more suitable current sensor solution.

Hangzhi High current sensor solution

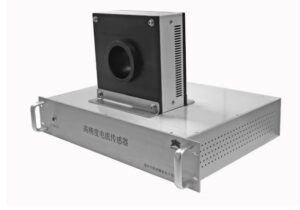

In order to solve the problems faced by the Hall current sensor, HangZhi proposed a high-precision high-current sensor solution based on the principle of fluxgate technology. The fluxgate principle current sensor is based on technical advantages, with a wider measurement range, higher accuracy and better performance stability. The maximum current measurement range is up to 8000A, and the accuracy can reach 50ppm. Its wide measurement range, high accuracy and fast response characteristics enable it to meet the requirements of the factory test of large-capacity photovoltaic inverters and ensure the quality and performance of photovoltaic inverters are stable. With the continuous expansion of the photovoltaic market, high-current sensors will play an increasingly important role in the industry and promote the further development of photovoltaic power generation technology.

Specifications of Hangzhi HIT Current Transducers

High precision: 50ppm

Measurement Range: 2000 to 8000A,

Full Scale Range: 1%-100% accuracy of a single product is consistent

Small temperature drift: good consistency, temperature influence, 0.1PPM/degree

Linearity: up to 20ppm

Wide Bandwidth: (up to 800kHz @±3 dB)

Response time: 1μs

Operating temperature range: -40..+85 °C

Stability (0.2 ppm/month)

AC and DC universal: can measure AC, DC, pulse current

Intelligent: load start overload protection, self-recovery

About Hangzhi

Shenzhen Hangzhi Precision Electronics Co., Ltd. is a technology-leading enterprise dedicated to the R&D, production, sales and solution customization of high-precision current sensors, voltage sensors, and high-precision electrical measuring instruments. We strive to build a well-known brand of precision current sensors and precision electrical measuring instruments in the DC field, and strive to develop into an international leading company in precision electronics in the field of DC systems.