What is fluxgate Current Sensor? Working principle of fluxgate sensor

Under the action of positive and negative excitation current, the easy-to-saturation magnetic core is used to make the inductance of the magnetic core change with the magnitude of the excitation current, so that the magnetic flux of the magnetic core changes continuously.

The fluxgate current sensor uses the non-linear relationship between the magnetic induction intensity and the magnetic field intensity of the high magnetic permeability core in the measured magnetic field under the saturation excitation of the alternating magnetic field to measure the weak magnetic field. This physical phenomenon seems to be a “gate” to the measured ambient magnetic field. Through this “gate”, the corresponding magnetic flux is modulated and an induced electromotive force is generated. This phenomenon is used to measure the magnetic field generated by the current, so as to indirectly achieve the purpose of measuring the current.

Basic Principles of Fluxgate Sensor Operation

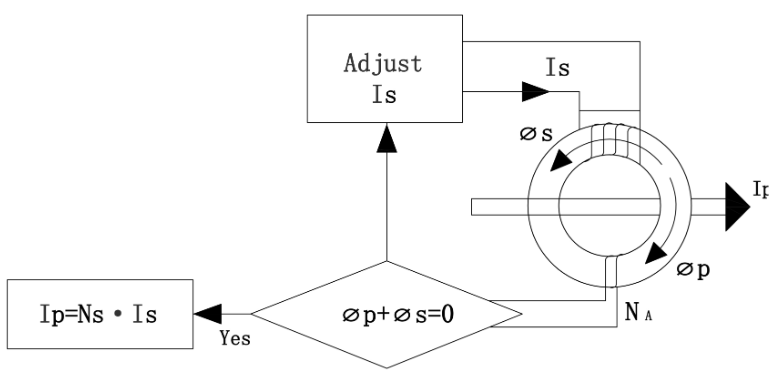

In the magnetic circuit, in order to detect a magnetic field equal to zero magnetic flux, the secondary coil must be excited by the necessary current. In the environment of zero magnetic flux, the current of the sensor is strengthened through the secondary coil, which is confirmed to be proportional to the measured primary current. . Ip=Ns. The Is ferromagnetic core and the auxiliary coil form a saturated inductor. In the case of zero magnetic flux, the detection of the sensor’s magnetic circuit is based on the change in the inductance of the inductor.

How does flux gate transducer technology evolves?

From the late 1960s to the early 1970s, fluxgate technology achieved a major breakthrough in accuracy for DC current measurement. The basic principle is to balance the magnetomotive force generated by the known current through the balance winding in the iron core and the magnetomotive force generated by the measured current to determine the magnitude of the measured current.

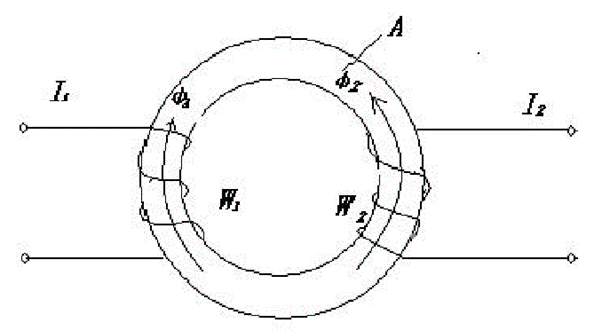

The principle structure of the fluxgate current sensor is shown in Figure in the right.

A is a high-permeability material core; W1 and W2 are proportional windings; I1 and I2 are supplied by two independent power sources with DC currents of W1 and W2 respectively; Φ1 and Φ1 are generated by proportional windings W1 and W2, respectively The magnetic flux; Rm is the magnetic resistance.

According to the law of electromagnetic induction, for fluxgate current sensors, as long as there is a current passing through the sensor, there must be an induced magnetic field, and the induced magnetic field is approximately linear with the current passing through the sensor, as long as the induced magnetic field can be accurately measured. The magnitude and direction of the external current can be measured indirectly. In addition, through in-depth research, it is found that after the fluxgate current sensor modulates the ambient magnetic field generated by the external DC current into an even harmonic induced electromotive force, not only the even harmonic content has an approximately linear relationship with the external DC current within a certain range, but also The average value of the even harmonic content has an approximately linear relationship with the external DC current within a certain range.

Hangzhi's Innovation based on traditional flux gate Transducer technology

Existing fluxgate current sensors have the problems of complex structure, high cost, and inability to realize wideband current detection, which limits their popularization to a certain extent. After years of painstaking research, Shenzhen Hangzhi Precision company invented the multi-point zero magnetic flux technolog, published on IEEE website: https://ieeexplore.ieee.org/document/8601521 .Through the zero magnetic flux closed-loop control of excitation magnetic flux, DC magnetic flux, AC magnetic flux and high-frequency magnetic flux, it realized the control of DC current and high-frequency current. As well as the precise detection of alternating current, the current detection accuracy of the sensor is improved, and the production cost of the sensor is reduced.

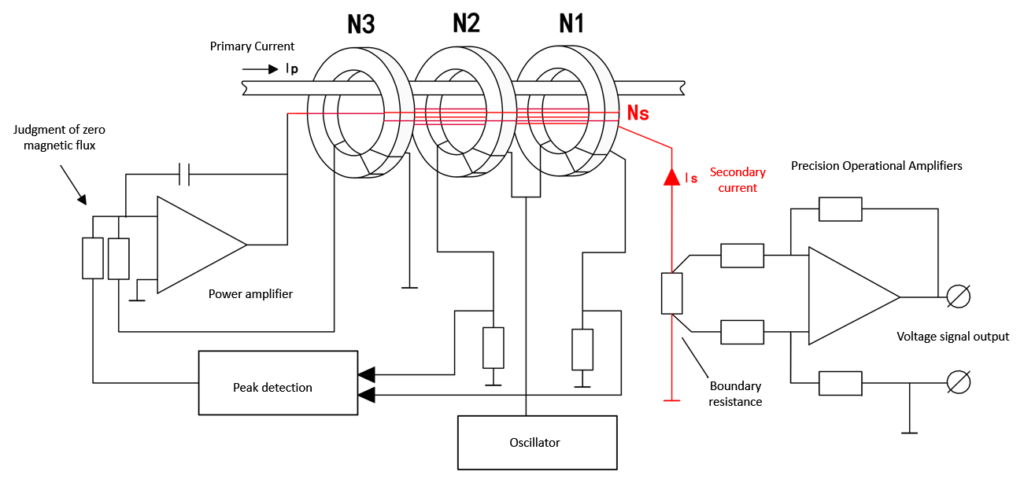

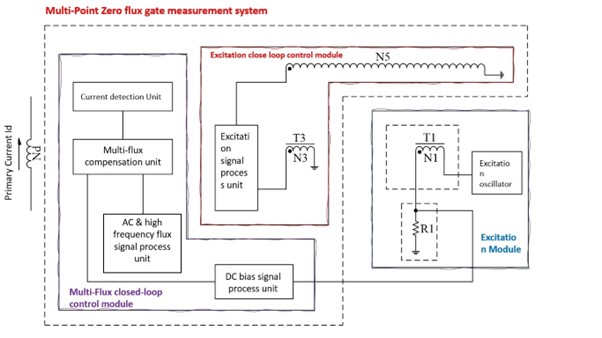

Multi-point zero magnetic flux technology control system, including excitation module, excitation magnetic flux closed-loop control module and multi-flux closed-loop control module.

The current Id in the circuit to be tested generates DC magnetic flux, AC magnetic flux, and high-frequency magnetic flux. The excitation oscillator outputs an alternating voltage signal of a preset frequency to the excitation unit to excite the excitation unit to generate excitation magnetic flux. The excitation magnetic flux detects the DC magnetic flux generated by the current Id to be measured, and outputs a DC magnetic flux signal corresponding to the DC magnetic flux.

The current Id in the circuit to be tested generates DC magnetic flux, AC magnetic flux, and high-frequency magnetic flux. The excitation oscillator outputs an alternating voltage signal of a preset frequency to the excitation unit to excite the excitation unit to generate excitation magnetic flux. The excitation magnetic flux detects the DC magnetic flux generated by the current Id to be measured, and outputs a DC magnetic flux signal corresponding to the DC magnetic flux.

Top Accuracy & Cost Effective

Fluxgate Precision Current Transducer Products

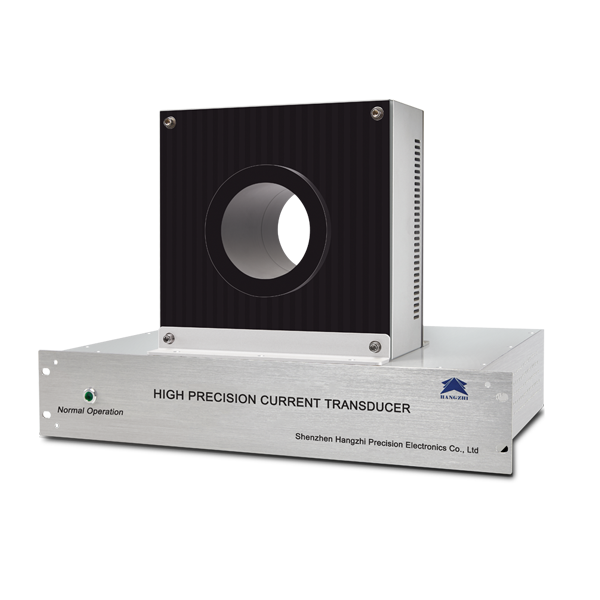

AIT High Precision Current Transducer

Range of Current Measurement: 1-10000A. Accuracy: 10ppm. Bandwidth: 800kHz/500kHz.

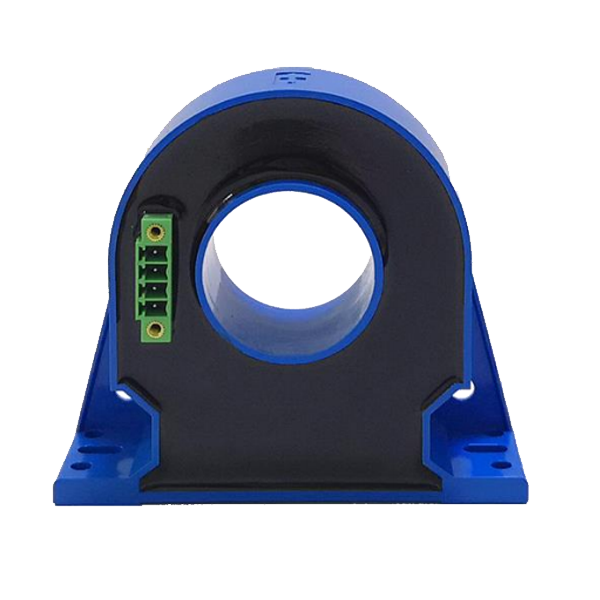

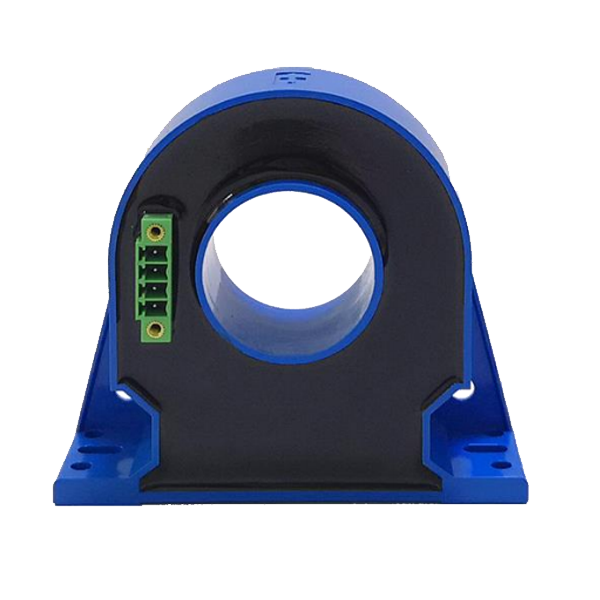

IIT Industrial Current Transducer

Range of Current Measurement: 1-10000A. Accuracy: 0.02%. Bandwidth: 100kHz.

HIT Hall Effect Substituting Current Transducer

Range of Current Measurement: 1-3000A. Accuracy: 0.05%. Bandwidth: 100kHz.

RIT Leakage Current Transducer

Range of Current Measurement: 10mA-10A. Accuracy: 0.2%. Bandwidth: 100kHz.

DIT High Precision Digital Current Transducer

Range of Current Measurement: 60A-2000A. Accuracy: 0.02%. Digital Signal Output: RS232/RS485.

High Current Transducer

Range of Current Measurement: 2000-10000A. Accuracy: 50ppm. Bandwidth: 300kHz/50kHz.

BMS Automotive Current Transducer

Range of Current Measurement: 300-1500A. Accuracy: 0.5%. Output: CAN digital signal.

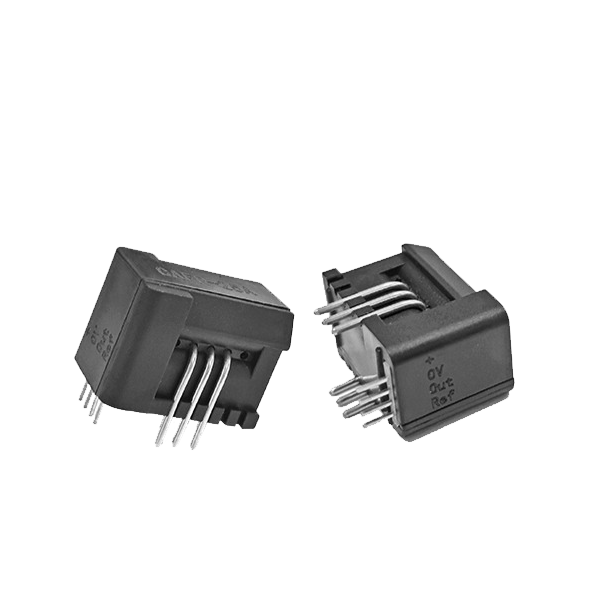

CAFR PCB Current Sensors

Range of Current Measurement: 6-50A. Accuracy: 0.8%.

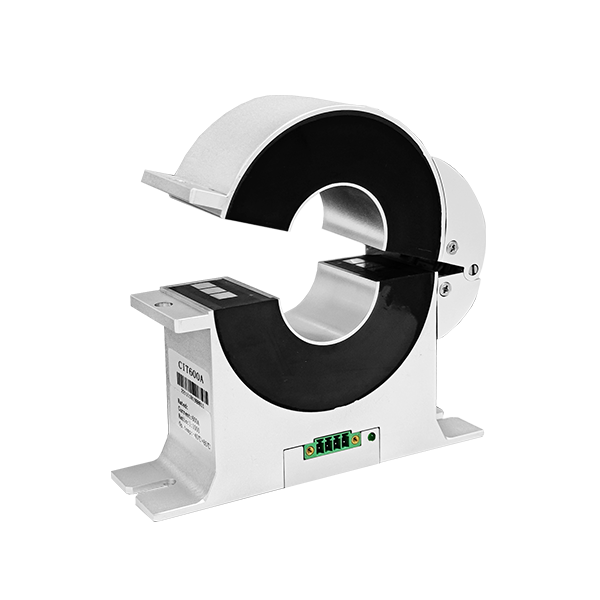

CIT High Precision Split Core Current Transducer

Range of Current Measurement: 100A-1500A. Accuracy: 0.05%. Bandwidth: 350kHz.

Pingback: what are the differences between fluxgate and hall effect current transducers? - Hangzhi Precision