When using current sensors, understanding their key characteristics can make the difference between accurate measurements and costly mistakes. Whether you are using them in industrial applications or for energy monitoring, proper knowledge is essential to achieve optimal performance. This blog will outline five important factors that should not be overlooked when using current sensors.

1. Voltage and current ratings of Current sensors

Each sensor is designed to operate at certain levels of current and voltage, exceeding these ratings can damage the device or cause incorrect readings.

If a sensor rated for low voltage is used in a system rated for high voltage, failures may occur.

Always match the specifications of the sensor to the system requirements to ensure safety and reliable performance. As a result, accidents can be avoided and the equipment will operate more efficiently.

2. Accuracy and Calibration of Current sensors

When using current sensors, accuracy is critical. Sensors measure current, and if they are inaccurate, your readings may be erroneous, leading to poor decisions.

Calibrating a sensor ensures that the measurements it provides are accurate. This process involves adjusting the device to a known standard so that it provides reliable readings. Regular calibration helps maintain accuracy over the long term.

Always check the accuracy of your sensor and calibrate it as needed, especially after extended use.

3. Output Signal Type of Current sensors

Different sensors can provide analog or digital output signals, and it is important to choose the right one for your system. Analog signals are continuous and are often used for real-time monitoring, while digital signals can be used for more precise measurements or easier integration with digital systems.

Make sure the output type matches the device or system you are using. This ensures seamless data transfer and accurate results.

4. Proper Installation

Improper installation can lead to poor sensor performance or even damage. Make sure the sensor is securely mounted and connected according to the manufacturer’s instructions.

Also, check that all wiring is done correctly to avoid electrical malfunctions. Improper installation can cause the device to read incorrectly or fail completely. Follow the installation guidelines carefully to ensure that the sensor works properly and prolongs its life.

5. Environmental Conditions

Factors such as temperature, humidity, and exposure to dust or chemicals can affect how well a device works. For example, high temperatures can cause a sensor to overheat, affecting its accuracy or causing it to malfunction.

Make sure the sensor is rated for the conditions in which it will be used. If the environment is harsh, consider using a sensor designed for those specific conditions. Protecting your device from extreme environmental factors ensures longer life and better performance.

Evaluating All Aspects of Current Sensors

By thoroughly understanding these factors, you can make an informed decision to achieve optimal performance and life. Be sure to take the time to carefully evaluate your current sensor needs in order to achieve the highest efficiency and accuracy in your application.

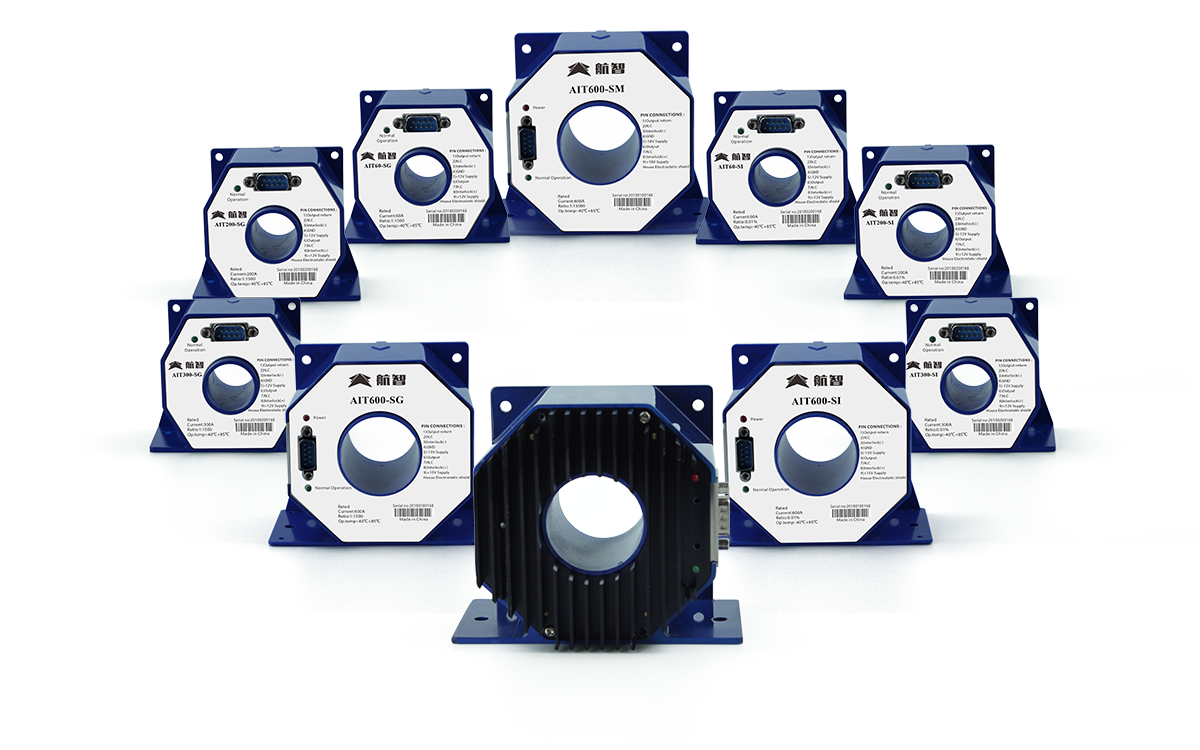

Über Hangzhi

Shenzhen Hangzhi Präzisionselektronik Co., Ltd. is a technology-leading enterprise dedicated to the research and development, production, sales and solution customization of high-precision current sensors, voltage sensors and high-precision electrical measuring instruments. We strive to build a well-known brand of fluxgate precision current sensors and precision electrical measuring instruments in the DC field, and strive to develop into an internationally leading leader in precision electronics in the field of DC systems.