The Most Important role of Current Sensors In Industrial Automation

In industrial automation, the precision and efficiency of electrical systems are essential for seamless operations. Current Sensors play a crucial role in optimizing these systems by enabling accurate monitoring, control, and management of electrical currents. By providing real-time data, enhancing safety, and facilitating predictive maintenance, these devices are revolutionizing industrial processes and boosting overall performance.

Understanding Current Sensors

Current Sensors, also known as current transducers or current transformers (CTs), are devices that measure and monitor the flow of electric current in a circuit. They work by converting the current passing through a conductor into a proportional output signal, which can then be analyzed by automation systems. Most Current Sensors are non-invasive, meaning they can measure current without direct contact with the conductors, making them ideal for automated and high-voltage applications.

Enhancing Safety and Reliability

Safety is a top priority in industrial settings, and Current Sensors play a significant role in preventing electrical hazards. Overloads, short circuits, and other electrical faults can cause serious risks, including fires, equipment failure, and personal injury. By continuously monitoring current levels, transducers can detect abnormalities and deviations from normal operating conditions. If an irregular current is detected, automated systems can trigger alerts or shut down operations to prevent further damage. This proactive approach significantly reduces the likelihood of accidents and downtime, making Current Sensors essential in high-risk environments such as power plants, chemical facilities, and heavy manufacturing industries.

Real-Time Monitoring for Improved Efficiency

One of the most valuable benefits of Current Sensors is their ability to provide real-time data on electrical system performance. In automated environments, continuous monitoring ensures that machinery operates within optimal parameters. By integrating real-time data into control systems, businesses can precisely regulate power distribution, identify inefficiencies, and optimize energy usage. This is particularly important in industries such as manufacturing, mining, and energy production, where efficiency and cost reduction are key priorities.

With the rise of Industry 4.0 and the Internet of Things (IoT), Current Sensors have become even more powerful. When combined with smart sensors, cloud computing, and artificial intelligence (AI), they can offer predictive analytics. This capability allows not only real-time current measurement but also early detection of potential system failures and inefficiencies, improving overall performance and reliability.

Enabling Predictive Maintenance

Predictive maintenance is another area where Current Sensors provide substantial benefits. By continuously monitoring electrical currents, these sensors can identify early signs of mechanical wear, motor stress, or component degradation. For example, if a motor begins drawing more current than usual, it could indicate mechanical resistance or an impending failure. Detecting these warning signs early enables businesses to perform maintenance before a failure occurs, preventing costly repairs, unexpected downtime, and operational disruptions.

This approach extends the lifespan of equipment while reducing maintenance costs. Instead of following a fixed maintenance schedule, companies can use data-driven insights to perform maintenance only when necessary. This leads to better resource management, lower operational costs, and increased efficiency.

Applications Across Various Industries

Current Sensors are widely used across multiple industries to improve automation and energy management. In manufacturing, they help monitor and regulate machinery energy consumption, ensuring cost-effective and energy-efficient production. In the power sector, they protect critical infrastructure and optimize energy distribution, helping to maintain grid stability and prevent power outages.

In renewable energy applications, Current Sensors monitor the performance of solar panels, wind turbines, and other energy generation systems. By providing accurate data on power output and system health, these sensors enhance the efficiency and reliability of renewable energy sources, supporting the transition toward sustainable energy solutions.

Abschluss

As industrial automation advances, Current Sensors continue to play an essential role in optimizing electrical systems. These devices improve efficiency, safety, and reliability while enabling predictive maintenance and energy optimization. By delivering real-time, precise data on electrical currents, they support industries in adopting smarter, more sustainable operational strategies. As businesses embrace digital transformation, Current Sensors will remain at the forefront of industrial automation, driving innovation and efficiency across various sectors.

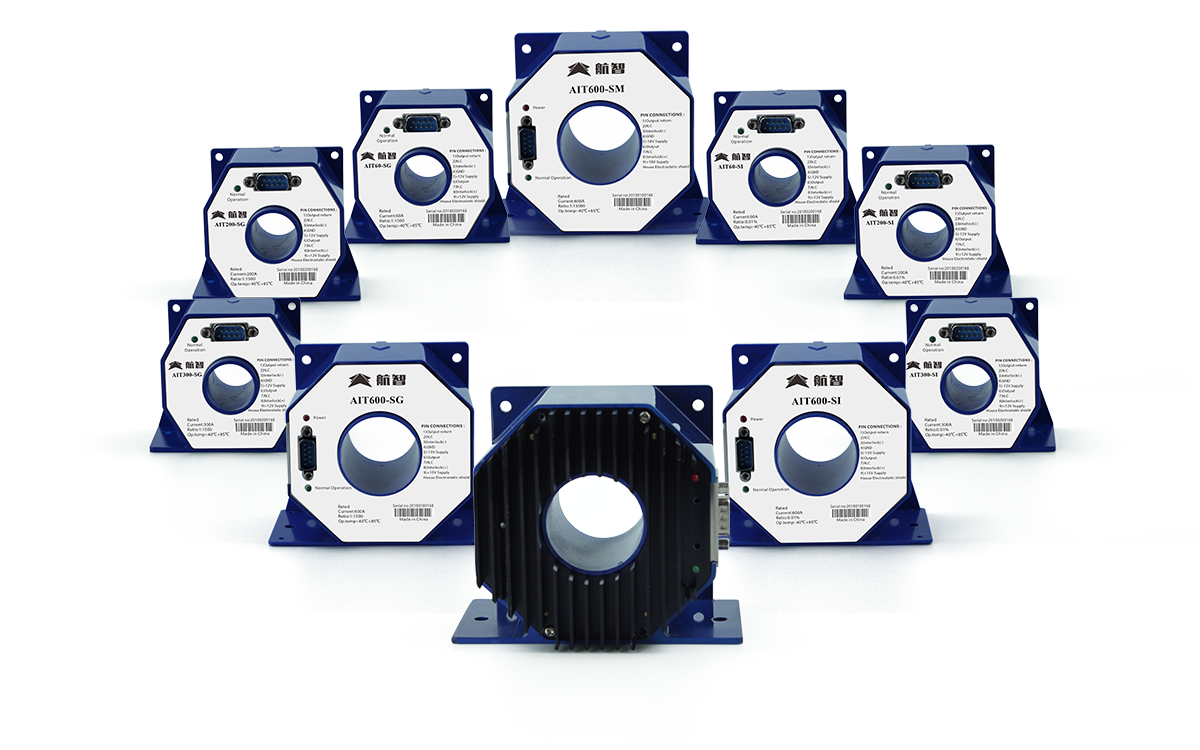

Über Hangzhi

Shenzhen Hangzhi Präzisionselektronik Co., Ltd. is a technology-leading enterprise dedicated to the research and development, production, sales and solution customization of high-precision current sensors, voltage sensors and high-precision electrical measuring instruments. We strive to build a well-known brand of fluxgate precision current sensors and precision electrical measuring instruments in the DC field, and strive to develop into an internationally leading leader in precision electronics in the field of DC systems.