What is current transducer?

Generally speaking, “current transducer”, also sometimes called “current sensor”, is a device used to measure the electric current flowing through a circuit. It converts the current to be measured, also called primary current either AC current or DC, into signal that can be measured by the control board or instruments, which is also called secondary signal and this signal can be current, voltage or even digital signal. Those current transducers play a critical role in various industries and applications, such as power electronics, power distribution, renewable energy, medical equipment, electrical calibration, electric vehicle and industrial automation etc.

View our range of current transducers here:

- AIT High Precision Current Transducers

- DIT High Precision Digital Current Transducers

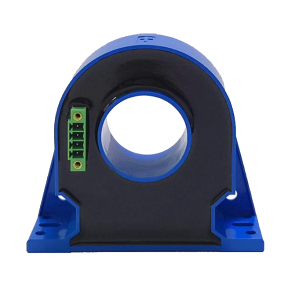

- IIT Industrial Current Transducers

- RIT Leakage Current Transducers

- HIT Hall Effect Substituting Current Transducers

- High Current Transducers

- CIT Precision Split Core Current Transducers

- CAFR Precision PCB Current Sensors

- BMS Automotive Current Sensors

What does a current transducer (CT) do?

A current transducer is an electrical device that measures or converts an electrical current for monitoring or control purposes. A current transducer does the following:

Current Measurement: A current transducer’s principal duty is to properly measure the magnitude of an electrical current flowing through a conductor. This current might be either alternating current (AC) or direct current (DC).

Isolation: Electrical isolation is frequently provided by current transducers between the input current and the output signal. This isolation is critical for safety and preventing interference between various components of an electrical system.

Signal Conversion: Current transducers frequently convert measured current into a proportionate output signal, which is typically in the form of voltage or current. This conversion facilitates communication with other electronic devices such as microcontrollers, PLCs (Programmable Logic Controllers), and data acquisition systems.

Amplification: Some current transducers may amplify the current signal in order to generate a more powerful and easily measured output. In certain applications, this amplification can help enhance the precision of current measurement. For the RIT leakage current sensor can convert the current with mini amperes into 1 or 2V voltage that is measureable by the PLC or microcontrollers.

Current transducers can have a variety of output kinds, such as voltage output (for example, output 0-10V current transducer), current output, frequency output, or digital communication protocols (for example, 4-20 mA current transducer or Modbus). The output type used is determined by the unique application needs.

Accuracy and Sensitivity: Current transducers are built to deliver precise measurements within a given range. To match the intended current range, they frequently include adjustable sensitivity or gain settings.

Hangzhi current transducers include protective mechanisms to defend against overcurrent circumstances and other electrical issues.

What is dC current Transducer or DCCT?

A DC current transducer, alternatively referred to as a DC current sensor, DC current converter or DCCT, is an electrical apparatus specifically engineered to gauge and transform direct current (DC) electrical signals into outputs that are proportionate to them. These outputs are commonly manifested as voltage, current, or digital data.

The principal purpose of a direct current (DC) current transducer is to furnish a precise and isolated depiction of the DC current under measurement. The achievement of this outcome is facilitated by the integration of various sensing devices like fluxgate or Hall sensor, signal conditioning circuitry, and output interfaces. The primary function of the sensing element is to detect direct current (DC) and transform it into a quantifiable signal. This signal is subsequently processed and adjusted by the signal conditioning circuitry. The output obtained is a faithful representation of the input current, but it is formatted in a manner that is compatible with other devices or systems for seamless integration.

What is aC current Transducer?

An AC current transducer, also known as an AC current sensor or AC current converter, is a device to generate an output that precisely represents the magnitude and attributes of the alternating current passing through a conductor, such as frequency and phase angle. The resulting output is commonly manifested as either a voltage signal, a current signal, or a digital signal, contingent upon the particular configuration and demands of the transducer.

It utilises several strategies to accomplish this conversion, fluxgate, electromagnetic, and optical methodologies. The sensing mechanism is responsible for detecting the magnetic or electromagnetic field that is produced by the alternating current (AC). Subsequently, this detected information is converted into a proportionate output signal by use of internal electronics.AC current transducers play a crucial role in a wide range of applications that require precise measurement and conversion of alternating currents.

AC Current Transducers are of paramount importance in various domains, including power distribution, energy management, motor control, and industrial automation, in terms of ensuring the efficiency, safety, and optimal operation of diverse electrical systems by facilitating precise monitoring of AC currents.

How does a current transducer work? and The current transducer principle

Contemporary transducers operate by transforming the primary electrical current passing through a conductor into a quantifiable secondary output. The working principle of current transducer may differ depending on the specific type of transducer employed. The following elucidates the fundamental operational principles of several prevalent current transducer types:

Fluxgate Current Transducers

Fluxgate transducers employ a core composed of a material exhibiting hysteresis characteristics. The magnetic state of the core undergoes alteration in response to the input current. The magnetic fluctuation is recognised and quantified, resulting in an output that is directly proportional to the input current.

Learn more about the detailed working principle of fluxgate current sensors, and the Hangzhi fluxgate current sensor and tester catalog.

Hall Effect Current Transducers

These transducers employ the Hall effect phenomenon, which refers to the production of a voltage disparity across a conductor in response to the application of a magnetic field that is perpendicular to the direction of current flow. The Hall sensor, when positioned near the conductor, is capable of detecting the voltage discrepancy, which is directly proportional to the current. The transducer serves to amplify and condition the voltage signal, so generating an output that accurately represents the input current.

Learn more about Hall Effect Current Transducers and the differences between fluxgate current transducers and hall effect current transducers.

Event though hall effect currrent transducers are the most popular for current sensing in the industry, a type of low-cost fluxgate current sensor is replacing some of the hall effect current sensor for better accuracy and linearity but with similar cost. Learn more about Hangzhi HIT hall effect substituting current transducers.

Rogowski Coil Transducers

Rogowski coil transducers are comprised of a coiled, flexible conductor looped around the target conductor. When an electric current passes through a conductor, it generates an electromotive force across the coil that is directly proportional to the rate at which the current changes. The induced voltage is integrated with respect to time in order to ascertain the precise value of the current.

Current Transformers (CTs)

Current transformers (CTs) consist of a primary winding that is linked in series with the conductor carrying the current, as well as a secondary winding. The magnetic field in the core is primarily generated by the primary winding, leading to the subsequent induction of a current in the secondary winding. The relationship between the secondary current and the primary current is one of proportionality, whereby the former is often reduced in magnitude to a level that can be conveniently measured.

Learn more about current transducer vs current transformers.

How to select current transducers and devices

The process of choosing the suitable current transducer necessitates the careful evaluation of various crucial variables to ascertain that the transducer adequately fulfils the unique demands of the given application. Presented below is a comprehensive sequential framework aimed at facilitating the process of decision-making, so enabling individuals to arrive at an optimal choice.

Type of Current

Determine whether you need to measure AC or DC current. This will narrow down your options to AC current transducers or DC current transducers.

Nowadays, fluxgate current transducer or hall effect current transducers can measure both DC and AC current. However, current transformer can only measure AC current, but cannot measure DC current.

Current Range

Define the minimum and maximum current levels you expect to measure. We normally need to leave about 10% to 20% engineering buffer of the actual primary current of the measurement and nominal range of the current transducer or current tester. Normally, the current transducers are labelled with DC current range, so when the measurement is AC, the nominal range should be calculated with 0.707. For example, a current transducer with DC1000A maximum range, can only measure 707A AC.

Nowadays, the current transducers can measure up to more than 10,000A, and down to 10mA with residual current transducer.

Accuracy Requirements

Identify the required level of accuracy for your measurements. Different transducers offer varying degrees of accuracy. Make sure the chosen transducer’s accuracy specifications match your needs.

This is another important parameter you will need to consider, as the current measurement accuracy is critical of the signal to send back to the controller, especially for the high precision requirement equipment, like MRI and high precision power supply or testing equipment.

However, thanks to the multi-point close loop zero flux gate technology, we are able to bring the high precision current measurement device down to an acceptable level.

AIT High precision current sensor can measure the current up to DC12000A with 10ppm accuracy;

Industrial current transducer can measure the current up to DC6000A as well with 0.02% accuracy;

The HIT zero flux gate hall effect current transducer replacement can achieve extremely low cost with 0.05% accuracy. This is a great replacement with similar cost for traditional hall effect current transducer, which normally have 0.5% to 2% accuracy.

Output Signal

The output type is another one to consider when selecting the current transducers, as normally it is more difficult to change the downstream equipment, mainly the Analogical input cards or controller. So it becomes easier to select the right signal output type to suit your controller or AI cards.

To meet most kinds of application requirements, most current transducer OEMs provide the following output signal types available:

Analogical signal;

Current signal:

Standard 4-20mA signal, for PLC AI modules;

Non-standard current signal, for power analyzers or multimeter etc.

Voltage signal:

±10V or 0-10V output current transducer, for example, AIT1000-10V;

Digital signal:

Some digital current sensor can also output the measured value via RS232/485 as well, this way the measured current can be transmitted back to controller or sever even easier.

Real-time display:

Most current testers, especially the portable DC current testers, don’t give high accuracy measurement. Thanks to the zero flux gate technology, there is high precision current tester and electrical standard tester can measure up to DC1500A with 0.02% accuracy with real time display. These testers are widely used in the electrical calibration laboratories and industrial applications, especially, a lot of EV battery OEMs use high precision current tester for calibration the battery discharge testing equipment.

Isolation Requirements

Assess the necessity of implementing galvanic isolation between the primary and secondary sides in your specific application. Ensuring safety and mitigating the occurrence of ground loops holds significant importance in this context.

Frequency Range or Bandwidth

When working with alternating currents (AC) or pulsed current, it is important to take into account the frequency range that is applicable to your specific application. Certain transducers may possess restricted bandwidth, thus it is advisable to select a transducer that is capable of effectively accommodating the desired frequency range.

Environmental Conditions

Environmental conditions encompass various aspects, including but not limited to temperature, humidity, and the presence of dust or corrosive compounds. Select a transducer that possesses the capability to endure the environmental conditions relevant to your specific application.

Installation Method & Physical Size

Method of Installation: The first step in the installation process involves determining the appropriate design for the application, such as a split-core or closed-loop design or is it for panel mounted, PCB mounted etc. Additionally, it is necessary to consider if a transducer that clamps around the conductor is required. Select a methodology that is pragmatic for the implementation procedure.

The dimensions are also critical to consider, and the customer can normally get STP file to integrate the current transducer model into their overal equipment design model to find out the if there is enough space or the aperture is big enough for the conductor to pass through.

Budget Considerations

Please ascertain the allocated budget for the acquisition of the transducer. In order to identify the most optimal solution in terms of value, it is imperative to carefully assess and weigh your requirements against the associated costs. On the current transducer market, there are sensor with high or low prices, and we will always be wise to spend our money.

Manufacturer Reputation and support

Selection of Transducers Based on Manufacturer Reputation: It is advisable to opt for transducers manufactured by well-established companies with a proven track record of delivering dependable and superior quality products. Conduct a thorough search for user reviews and industry recommendations.

In cases of uncertainty regarding the optimal transducer for a specific application, it is advisable to seek advice from technical experts or manufacturers’ support teams.

Get In Touch with our Experts

Contact us directly via email info@hangzhiprecision.com or fill out the form below. We will respond as soon as possible.